Saturn Rocket Stage

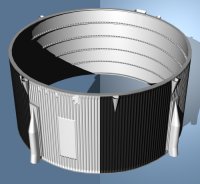

APOLLO Apollo spacecraft SaturnV S-IC First Stage

S-IC First Stage

Diameter : 33ft (10.06m)

Height : 138ft (42.06m)

Weight(dry) : 303000lb (137.44ton)

Weight(loaded) : 4881000lb(2213.97ton)

Manufacturer : The Boeing Co. New Orleans

Burn time : 2.5min approx.

Velocity at burnout : 6000mph(9654km/h)

Altitude at burnout : 38miles(61.14km)

S-IC structure consists of five units of Forward Skirt, LOX Tank, Intertank,

FUEL Tank, Thrust Structure from the top. And, five F1 engines, eight Ullage

Rockets in fairings are carried on this.

Forward Skirt Assembly

The independent two DC28V batteries, the electric power source to manipulate

variety units of the S-IC are carried here. No.1 battery is called the main

power battery, has 640 ampere-minute rating, and is 22 pounds. This is used

to control various solenoids. No.2 battery is called the instrumentation

battery, has 1,250 ampere-minute rating, and is 55 pounds. This is used for

flight measurement and redundant systems.

And, here is telemetry transmitter by six kinds of frequency. Most of

telemetry systems units are mounted on Thrust Structure, RF transmitter and

tape recorder are mounted on this Forward Skirt Assembly. At the time of

ullagerocket, retrorocket jetting, telemetry transmission is disturbed. So,

at that time, data will be recorded by tape recorder, and will be

transmitted later. The control of this tape recorder is performed by the

digital computer carried on IU.

Furthermore, ODOP (Offset Doppler Tracking) system to tracking movement of

the rocket is carried here. High frequency signal from the ground is

received with this ODOP system, then sent back again to the ground. The

ground can know the movement of the rocket from doppler shift of the

frequency.

With APOLLO 4 and 6, four color film cameras are carried here, make a film

of the inside of LOX tank during the flight. The capsule that camera and

film are stored is separated 25 seconds after the S-IC separation, parachute

is opened and splash down, collected with the help of the signal of radio

beacon.

LOX Tank Assembly

331000 gallons (about 1426ton) of LOX (Liquid Oxygen) of -297 degree

Fahrenheit are carried here. Through five LOX suction lines, 2000 gallons (about

19ton) of LOXs are supplied to the F1 engine per 1 second in flight. Cut-off

sensor is being installed in the top end part of this LOX suction line. When

it is detected that LOX disappeared by this, engines are stopped.

LOX is injected from two Fill & Drains located at the bottom of the tank

with 1500 gallons per minute until they become 6.5% of the tanks. It is

poured at 10000 gallons per minute until it meets 95% when it exceeds 6.5%.

Then, it is poured until it is 100% at 1500 gallons per minute at the end.

When temperature of LOX rose, cooling is done by sending the bubble of the

helium to the inside of LOX suction line. And, this helium and oxygen,

nitrogen are used for pressurize of LOX. 45 seconds before launch, Helium is

poured until pressure becomes 26psia through GOX (Gaseous Oxygen)

distributor located at the top of the LOX tank from ground equipment. Then,

pressurize is done during the flight as a part of LOX is heated by the heat

of the engine and returning it to the LOX tank.

Intertank Assembly

This ring-shaped structure is located between LOX Tank and FUEL Tank, and

connect those modules. Here is the access door for the maintenance and

various connectors called umbilical opening. A LOX outlet for the emergency,

pressurize port, electric connector and so on is contained in this umbilical

opening.

FUEL Tank Assembly

The fuel used by S-IC is a kind of kerosene called RP-1. 203000 gallons (about

630ton) of RP-1s are carried on this fuel tank. Through 10 Fuel suction

lines, 1350 gallons (about 4ton) of RP-1 are supplied to the F1 engine per 1

second in flight. The pipe which makes the bubble of nitrogen is installed

in Fuel suction line. Temperature of the fuel is prevented from rising

before launch using this pipe. And five LOX suction lines are passing in

this tank for supply LOX to F1 engines.

Fuel is injectioned at 200 gallons per minute from Fill & Drain located at

the bottom of the tank until they become 10% of the tanks. It is poured at

2000 gallons per minute until it meets 102% when it exceeds 10%.

Pressurize of fuel is done by the helium supplied by four high pressure

bottles located in the LOX tank. This helium is sent to the F1 engine once

and heated. Then, it is returned to the fuel tank again, and used for

pressurize.

And, fuel is used as the fluid power to change the direction of the engines

during the flight. Fuel is sent to servo actuator from high pressure fuel

duct during the flight.

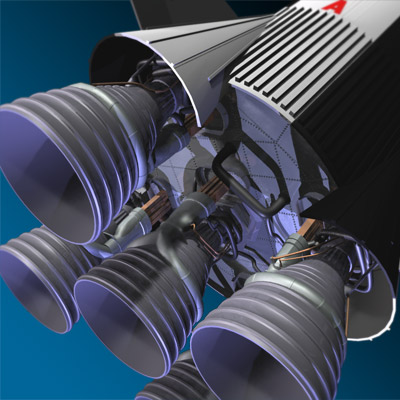

Thrust Structure Assembly

Thrust Structure which F1 engine is installed is heavy (24ton) parts in S-IC.

These parts support the whole weight of the rocket, and all the thrust of

the engine is transmitted to the body. Four holddownposts are being

installed here. These are used for pressing down a rocket on the launch pad

until get enough thrust after F1 engine ignite. Fuel supply, LOX outlet, and

so on are being installed here. And four fins and fairings are installed

surround F1 engines. In each fairings, two Retro (reverse jetting) Rocket

are built in respectively. These fins are installed to give a vertical

rocket stability, and heated in 200 degree Fahrenheit during the flight due

to the air friction. Fins are covered with titanium to hold out this heat. A

fair ring is blown off when Retro (reverse jetting) Rocket ignited.

Range Safety System

This system stops an engine with the command from the ground, burst fuel

tank, throw fuel away in the air, in the emergency. When a proper command is

received from the ground, redundant Safety Command Receiver stops an engine,

fire Shaped Charge, and tank is exploded.

S-IVB Third Stage

S-IVB, the third stage of Saturn V booster, is made APOLLO spaceship which has already reached the earth orbit to go to the flight (Trans lunar injection : TLI) to the moon. Then, it continues the flight to the moon itself, and crashes on the moon at the end.

Diameter : 21ft 8in (6.604m)

Height : 58ft 7in (17.8562m)

Weight(dry) : 33600lb (15.24ton) (include 7700lb Aft.Interstage)

Weight(loaded) : 265600lb(120.47ton)

Manufacturer : McDonnell Douglas Astronautics Co. Huntington Beach, Calif.

Burn time:

1st burn : 2.75min approx.

2nd burn : 5.2min approx.

Velocity at burnout:

1st burn : 17500mph approx.(28157.5km/h)

2nd burn : 24500mph approx.(39420.5km/h)

Altitude at burnout:

1st burn : 115mile approx.(185km)

2nd burn : translunar injection

S-IVB structure consists of five units of Forward Skirt, Propellant Tank,

Thrust Structure, Aft Skirt, Aft Interstage from the top. And, one J2

engine, two Ullage Rockets, two sets (eight nozzles) of Auxiliary Propulsion

System, four S-II retro rockets are carried on this.

Forward Skirt Assembly

The extreme top of the body, ring-shaped part to connect IU is Forward Skirt

Assembly. This is made from aluminum, and equipped with the environmental

conditioning system which cools various an electronic machine, an antenna

and them. This environmental conditioning system is controlled by IU. Here

is equipped with the two DC28V batterys, too. Two telemetry antennas

transmit digital signals that PCM/FM moderated to the ground, the variety

information of the stage.

Propellant Tank Assembly

It is a fuel tank, the center of the body is greatly occupied. The top of

about 3/4 is the LH2 (Liquid Hydrogen) tank, and the remainder, about 1/4 of

bottom part is the LOX (Liquid Oxygen) tank. And, eight circle helium tanks

are being installed inside the LH2 tank, for apply pressure to push the fuel

out to engines. This tank is made of aluminum alloy, and waffle pattern was

cutting down in inside for weight reduction and strength reinforcement. The

ring-shaped board called slosh-baffle is being installed inside the LOX tank

to prevent liquid oxygen from being choppy during the flight. Tile-shaped

fiberglass insulation is stuck inside the LH2 tank. Fuel is poured slow

speed at the beginning of injection, to wait for chill down the tank. High-speed

injection is done next. Then filled slowly until it becomes 100% at the end.

When finished the injection, before launch, kept supplying the fuel that

lost by the vaporization.

LOX

temperature : -297 degrees Fahrenheit

pressure : 38-41psia

Fuel injection speed :

5% of tank : 500gpm(gallons per minute)

98% of tank : 1000gpm

100% of tank : 0-300gpm

LH2

temperature F-423 degrees Fahrenheit

pressure : 31-34psia

Fuel injection speed :

5% of tank : 500gpm(gallons per minute)

98% of tank : 3000gpm

100% of tank : 0-500gpm

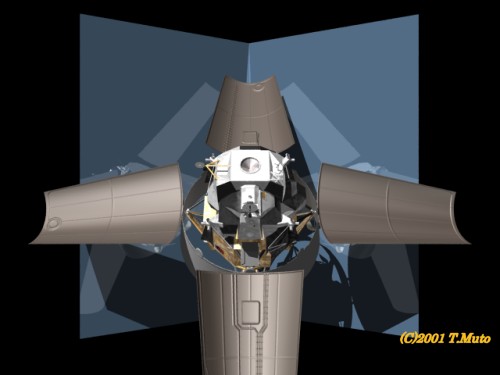

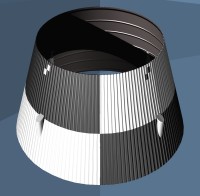

Thrust Structure Assembly

Thrust Structure Assembly is the cone-shaped in the bottom part of the body,

equipped with the J2 engine. Engine gimbal system, spare circle helium tank,

O2/H2 burner and so on are carried here too. This O2/H2 burner is used for

warming up the helium which got cold too much when the second time burn for

TLI.

Aft Skirt Assembly

The extreme bottom part of the body, a ring-shaped part to connect Aft

Interstage is Aft Skirt Assembly. Two set of posture control rockets (Auxiliary

propulsion system : APS), two Ullage Rockets, one DC28V battery and one

DC56V battery is carried here. APS is was completely independent rocket

system with S-IVB. It has an private liquid fuel tank in that, and can be

controlled in 3 axis. Ullage Rocket is solid fuel rocket to increase the

acceleration to press fuel inside the tank at the bottom. It ignites before

J2 engine jetting, and is jettisoned after use.

Aft Interstage Assembly

Aft Interstage Assembly

This cone-shaped part is connected smooth aerodynamically between S-IVB and

S-II. This part is fixed on S-II and four reverse jetting rockets (Retro

Rocket) for S-II are built in.

Jettison

Jettison control unit between S-II and S-IVB is equipped on S-II. This S-II

Flight Sequencer transmitt pulse signals to the disjunction device (EBW)

which is equipped on S-IVB after three seconds of S-II engine cut off. Then,

fire signal of 2300V is sent to the fuse (MDF) from EBW, and jettisoned.

Next, four Retro Rocket carried on Aft Interstage are jetted by S-II Flight

Sequencer for 1.5 seconds. S-II leaves S-IVB by this.

Range Safety System

On Forward Skirt, two RangeSafety antennas are carried. When an emergency

occurred, this system catch a signal from the ground and starts the spark

plug and cleaves LOX and LH2 tank.

S-II Second Stage

It is six minutes that S-II is used after the separation of the S-IC. By using this power, APOLLO is lifted from 200,000 feet (60km) to about 606,000 feet (184km).

APOLLO Apollo spacecraft SaturnV S-Ihhe

Diameter : 33ft (10.06m)

Height : 81ft 7in (24.87m)

Weight(dry) : 95000lb (43.09ton)

Weight(loaded) : 1037000lb(470.37ton)

Manufacturer : North American Rockwell Corp. Space Div. Seal Beach, Calif.

Burn time : 6min approx.

Velocity at burnout : 15300mph(24617.7km/h)

Altitude at burnout : 114.5miles(184km)

S-II structure consists of five units of Forward Skirt, LH2 Tank, LOX Tank,

Aft Skirt and Thrust Structure, Aft Interstage from the top. And, five J2

engine, four Ullage Rockets are carried on this.

Forward Skirt Assembly

The LH2 pressurize system, telemetry antennas, and various measuring units

are stored here. The telemetry system measures the pressure of the tank,

temperature, fuel flow, the vibration of the body, noise, a position,

acceleration, and so on. This antennas are being installed on the surface of

Forward Skirt flatly, and it is omnidirectional.

LH2 and LOX Tank Assembly

It is the fuel and oxidizer tank to occupy the center of S-II's own. Fuel is

LH2 (liquid hydrogen) of 260000 gallons (153000 pounds) of -423 degrees

Fahrenheit, and LOX (liquid oxygen) of 83000 gallons (789000 pounds) of -297

degrees Fahrenheit. The weight of this fuel occupies more than 90% of the

all S-II's weight. This tank is made of the light weight aluminum alloy, and

the insulation of the special light weight is spread inside. This insulation

insulates 500 degrees Fahrenheit betwwen the air and the fuel in 1.5-inch

thickness. The top 3/4 is the LH2 tank made of six cylinder shape rings. A

bottom part 1/4 is oval shape LOX tank. Systems Tunnel of 60 feet is being

installed outside the tank from the top to the bottom. The variety electric

cable which connects Aft Skirt with Forward Skirt passes in this.

Purge Subsystem

Before putting fuel in the LH2 tank, air inside the tank must remove oxygen

completely. Or, Oxygen is frozen in the LH2 tank, then when a vibration is

received, it reacts with LH2 and explodes. Therefore, before the fuel

injection, until oxygen is discharged, it is repeated that helium is poured

from the ground establishment and exhausted.

Fill and Replenish Subsystem

LOX and LH2 are poured slow speed at the beginning of injection, to wait for

chill down the tank. High-speed injection is done next. Then filled slowly

until it becomes 100% at the end. When finished the injection, before launch

(LOX 160 sec. before, LH2 70 sec. before), kept supplying the fuel that lost

by the vaporization.

LOX

temperature : -297 degrees Fahrenheit

pressure : 37-39psia

Fuel injection speed :

5% of tank : 500gpm(gallons per minute)

98% of tank : 5000gpm

100% of tank : 0-1000gpm

LH2

temperature : -423 degrees Fahrenheit

pressure : 31-33psia

Fuel injection speed :

5% of tank : 1000gpm(gallons per minute)

98% of tank : 10000gpm

100% of tank : 0-1000gpm

Venting Subsystem

Two exhaust valves are set up in each of LOX, LH2 tank. This is opened at

the signal from the ground at the time of the fuel injection, and used for

removing the gas which vaporized in the tank.

Pressurization

Pressurize of S-II is done by pouring helium from the ground establishment

before launch. After the J2 engine start, pressurize is done by vaporized

LOX, LH2 by the heat of J2 engine.

Aft Skirt and Thrust Structure Assembly

Five J2 engines, fuel feed lines, and various electronic control units are

being installed here. Then, hard heat sheld is being installed around the J2

engine.

Aft Interstage Assembly

This is semi-monocock structure of the cylinder shape of the height 18feet (about

5.5m), the diameter 33feet (about 10m), and Ullage rocket motor of 8(SA-500F,SA-501,SA-502)

or 4(SA-503`SA-509) are carried on the outside. (After SA-510 mission,

Ullage rockets are not carried)

[Ullage]

An old brewer's term referring to the gaseous zone in a tank above the

liquid.

S-IC jettison

After F1 engine stops and S-IC is separated, Ullage rocket motor on Aft

Interstage jets for about four seconds. By this action, fuel is pressed

against the bottom part of S-II tank, and sent to the J2 engine. After about

30 seconds of the S-IC jettison, Aft Interstage is separated with Ullage

rocket motors. As for the separation of this Aft Interstage, extreme

precision is required by control. It must be done not to collide with the J2

engine in that with continuing high speed flight. There is only the 3feet

(1m) gap between Aft Interstage and the J2 engine. This two-step separation

of S-IC and interstage is called "dual plane separation".

S-IVB Second stage

S-IVB stage is the improved S-IV stage from Saturn I for Saturn V. S-IVB stage for Saturn IB is developed by modify Saturn V S-IVB.

APOLLO - Apollo spacecraft Saturn IB S-IVB Second Stage

Saturn 1b

Instrument Unit(IU)

IU is a computer system controls whole of Saturn rocket. This was made by common design through all the series of Saturn I, IB, V.

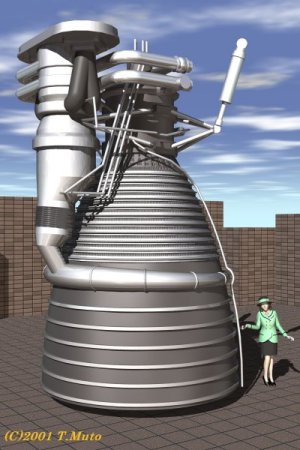

F1 Engine

Width : 12ft 4in (3.76m)

Length : 19ft (5.79m)

Thrust(sea level) : 1,500,000lb (680.39ton)

Rated run duration : 150sec.

Manufacturer : North American Rockwell Corp., Rocketdyne Div. Canoga Park,

Calif.

Thrust updated to 1,522,000lb(690.36ton) for SA-504 and later mission.

Hiçbir yazı/ resim izinsiz olarak kullanılamaz!! Telif hakları uyarınca bu bir suçtur..! Tüm hakları Çetin BAL' a aittir. Kaynak gösterilmek şartıyla siteden alıntı yapılabilir.

© 1998 Cetin BAL - GSM:+90 05366063183 -Turkiye/Denizli

Ana Sayfa / Index / Roket bilimi / E-Mail / Rölativite Dosyası

Time Travel Technology / UFO Galerisi / UFO Technology/

Kuantum Teleportation / Kuantum Fizigi / Uçaklar(Aeroplane)

New World Order(Macro Philosophy) / Astronomy